There are four characteristics of hemp which make it particularly appealing for making paper:

☮Hemp

fibres are long (makes for stronger paper which can be recycled more

times than wood paper);

☮Hemp

fibres are long (makes for stronger paper which can be recycled more

times than wood paper); ☮Hemp contains high levels of cellulose (57-77%) and more cellulose makes for more pulp;

☮Hemp

has low (3%) lignin content (this is what makes wood-pulp paper turn

yellow over time);

☮One

acre of hemp can produce as much usable fibre as four acres of

trees. Hemp can be harvested every 100 days. Trees take decades

to harvest.

The

best part about hemp-based paper is that its production is

environmentally friendly. Wood paper? Not so much …

Due

to its chemical

and physical composition, hemp can produce high pulp yields and can

be pulped without use of the Kraft process (chemical pulping

of wood and long-fibre speciality papers) which uses sulphur

compounds that are environmentally toxic. Also, as with other

non-wood pulp, hemp can be bleached with peroxide and through other

processes that do not involve chlorine.

Due

to its chemical

and physical composition, hemp can produce high pulp yields and can

be pulped without use of the Kraft process (chemical pulping

of wood and long-fibre speciality papers) which uses sulphur

compounds that are environmentally toxic. Also, as with other

non-wood pulp, hemp can be bleached with peroxide and through other

processes that do not involve chlorine.

2) We

can build stronger homes with it, use less lumber and create carbon

neutral structures

Hemp

has some fascinating qualities for a natural fibre. One of the

building products made from hemp is called Hempcrete.

It’s a good acoustic dampener, it breathes (doesn’t trap

vapours and humidity) and is a good insulator. And while it doesn’t

have great potential as a structural (load-bearing) material on it’s

own, it does have exciting possibilities as insulation that strengthens the existing structure. Hempcrete infill can

increase, up to 4 times, the strength of a timber wall by preventing

weak axis buckling by acting as continuous lateral elastic support.

With

Hempcrete, construction costs are reduced by: shallower

foundations; 30-40% less lumber, labour in framing; lower

transport costs of materials to site; lower finish costs; discounted

insurance costs; reduced mechanical (HVAC) requirements; NO

termite fumigation needed after build

Another

product, called Cannabric,

can be used as a load bearing material for buildings of multiple

floors. It provides much of the same acoustic, insulating and

breathing benefits of Hempcrete, but it can also replace nearly all

of the lumber or steel support used in typical construction.

|

The

mineral components of the Cannabric are

responsible for its mechanical hardness, its density and its

excellent thermal inertia. The result is a brick of low thermal

conductivity (0,1875 W/m·K) and high specific thermal capacity (1291

kJ/m3·K); it possesses thermo-physical characteristics to protect

against both cold and hot climates. All this with one-layer walls of

small thickness, without additional thermal insulation.

Another

fascinating benefit of almost every hemp-based building material is

that they are carbon negative. No, not carbon neutral, but carbon

negative. In other words, hemp absorbs so much carbon from the

atmosphere while it is growing that even the gas-powered machines

used to harvest it, to manufacture it and to transport it do not

equal as much carbon as it has already absorbed. Cannabric has a

GWP (Global Warming Potential) of -0.624 kg CO2 eq/kg, that means

negative. It is a material that retains CO2. In its manufacturing

processes (materials, transport, used energy) it does not contribute

to global warming.

3)

We can fuel our cars with hemp 'gasoline' (petrol) and bio-diesel and

stop burning fossil fuels

We’ve

all heard of bio-diesel, and any vegetable oil can be made into

bio-diesel. What’s really a game-changer is hemp can be used to

make 'green

gasoline',

almost identical to the stuff we currently put into our

combustion engine vehicles, but derived completely from cellulose.

In 2008, US researchers made a breakthrough in the development of

green gasoline, a liquid identical to standard gasoline, created

from sustainable biomass sources. Chemical

Engineer George

Huber of

the University of Massachusetts-Amherst (UMass) and his graduate

students announced the first direct conversion of plant cellulose

into gasoline components. "Green gasoline is an attractive

alternative to bio-ethanol since it can be used in existing engines

and does not incur the 30% gas mileage penalty of ethanol-based flex

fuel. In theory it requires much less energy to make than ethanol,

giving it a smaller carbon footprint and making it cheaper to

produce. Making it from cellulose sources such as switchgrass or

poplar trees grown as energy crops, or forest or agricultural

residues such as wood chips or corn stover, solves the life-cycle

greenhouse gas problem that has surfaced with corn ethanol

and soy bio-diesel", said John Regalbuto at the US National Science

Foundation (NSF) who supported this research.

"Huber's ... process for the direct conversion of cellulose to gasoline aromatics is at the leading edge of the new ‘Green Gasoline' alternate energy paradigm that NSF, along with other federal agencies, is helping to promote. Not only is the method a compact way to treat a great deal of biomass in a short time, the process, in principle, does not require any external energy. In fact, from the extra heat that will be released, you can generate electricity in addition to the bio-fuel. There will not be just a small carbon footprint for the process; by recovering heat and generating electricity, there won't be any footprint."

And

it turns out, hemp is the best plant in the world to produce biomass

for cellulosic gasoline. According to the paper Energy

Farming in America,

"Hemp is the world’s most versatile plant. It can yield 10

tons per acre in four months. Hemp contains 80% cellulose; wood

produces 60% cellulose. Hemp is drought resistant making it an ideal

crop in the dry western regions of the country".

Once

this technology has evolved sufficiently to be cost effective on a

large scale, it will confirm that hemp, Cannabis sativa, is a

superior cultivar for bio-fuel production. Hemp exhibits far superior

ethanol yields per unit biomass compared to corn or switchgrass which

are the two most supported cultivars for bio-fuel by the US

government.

Industrial

hemp on a large scale is not a crop considered viable in Australia by

the Australian government.

If

the production of cellulosic gasoline (supplied by hemp) ramps up to

the point that most vehicles can be fuelled with it, simply using

cellulosic gasoline will reduce greenhouse gas emissions (GHG) by 85%

compared to reformulated petrol or ethanol.

4)

We can start to solve world hunger with the complete proteins and

amino acids of hemp seeds

Hemp

is cheap to grow, and it grows almost everywhere. So we could grow a

whole lot of it for very little. And while we're using all that

cellulose from hemp’s biomass to make gasoline (petrol) and clothes

and better materials for our homes, we could be using the seeds for

food.

Technically a nut, hemp seed typically contains over 30% oil and about 25% protein, with considerable amounts of dietary fibre, vitamins and minerals. Hemp seed oil is over 80% polyunsaturated fatty acids (PUFAs) and an exceptionally rich source of the two essential fatty acids (EFAs) linolenic acid (18:2 omega-6) and alpha-linolenic acid (18:3 omega-3). The omega-6 to omega-3 ratio (n6/n3) in hemp seed oil is normally between 2:1 and 3:1, which is considered to be optimal for human health. In addition, the biological metabolites of the two EFAs, gamma-linolenic acid (18:3 omega-6; ‘GLA’) and stearidonic acid (18:4 omega-3; ‘SDA’), are also present in hemp seed oil. The two main proteins in hemp seed are edestin and albumin. Both of these high-quality storage proteins are easily digested and contain nutritionally significant amounts of all essential amino acids. In addition, hemp seed has exceptionally high levels of the amino acid arginine. Hemp seed has been used to treat various disorders for thousands of years in traditional oriental medicine. Recent clinical trials have identified hemp seed oil as a functional food and animal feeding studies demonstrate the long-standing utility of hemp seed as an important food resource.

Technically a nut, hemp seed typically contains over 30% oil and about 25% protein, with considerable amounts of dietary fibre, vitamins and minerals. Hemp seed oil is over 80% polyunsaturated fatty acids (PUFAs) and an exceptionally rich source of the two essential fatty acids (EFAs) linolenic acid (18:2 omega-6) and alpha-linolenic acid (18:3 omega-3). The omega-6 to omega-3 ratio (n6/n3) in hemp seed oil is normally between 2:1 and 3:1, which is considered to be optimal for human health. In addition, the biological metabolites of the two EFAs, gamma-linolenic acid (18:3 omega-6; ‘GLA’) and stearidonic acid (18:4 omega-3; ‘SDA’), are also present in hemp seed oil. The two main proteins in hemp seed are edestin and albumin. Both of these high-quality storage proteins are easily digested and contain nutritionally significant amounts of all essential amino acids. In addition, hemp seed has exceptionally high levels of the amino acid arginine. Hemp seed has been used to treat various disorders for thousands of years in traditional oriental medicine. Recent clinical trials have identified hemp seed oil as a functional food and animal feeding studies demonstrate the long-standing utility of hemp seed as an important food resource.

What

could be accomplished if hemp were being grown in large quantities

all over the world for fuel, for clothing, for paper and so on? How

many could we feed with all those hemp seeds?

5)

We can make clothing and fabrics with a fraction of the environmental

impact and water consumption of cotton

For

millennia, humankind has made clothing from hemp’s long, strong

fibres. Turning to hemp as a source of textile fabric would actually

be a re-turning to hemp. The environmental impact of increased

hemp production over cotton would be tremendously positive. Cotton

requires more water, more fertilisers, more herbicides and more

pesticides to grow.

Hemp

represents the lowest ecological footprint of the three textiles. The

footprint of hemp does not vary significantly in the different case

studies, starting at 1.46 g/ha and reaching 2.01 g/ha. As with

cotton, crop cultivation represents the greatest proportion of the

ecological footprint in the hemp case studies. Again, this can be

attributed to the land area required to grow the crop. However,

unlike cotton, hemp productivity

levels are much greater with yields of up to 3 tonnes of dry fibre

per hectare compared to 1.35 tonnes of cotton lint per hectare.

When

it comes to water needs, cotton loses by a landslide to hemp. It

takes just over 4,474 litres (1,182 gallons) of water to

produce 0.45 kg (1 lb) of usable cotton. It takes

over 961 litres (254 gallons) of water to produce 0.45 kg (1 lb)

of usable hemp fibre.

6)

We can reverse / negate the effects of carbon emissions on global

warming

Through carbon

bio-sequestration,

a process of capturing carbon emissions from the atmosphere through

plants, we can trap or, 'sequester', carbon from the air into plants.

Once the plants are harvested we can then create a substance

called biochar,

not through burning the plants, but slow-smouldering them to create a

form of charcoal, which we then mix with nutrients and bury back into

the soil.

The

ancient tribes of the Amazon had this process figured out a long time

ago. There’s a particular type of soil made from this active human

interaction called 'terra preta' and it’s spectacular stuff.

Compared with the surrounding soil, terra

preta can

contain three times as much phosphorus and nitrogen.

Leaving

aside the subtleties of how char particles improve fertility, the

sheer amount of carbon they can stash away is phenomenal. In

1992, Sombroek published his first work on the potential of terra

preta as a tool for carbon sequestration. According to Glaser’s

research, a hectare of metre-deep terra preta can contain 250 tonnes

of carbon, as opposed to 100 tonnes in unimproved soils from similar

parent material. The extra carbon is not just in the char — it’s

also in the organic carbon and enhanced bacterial biomass that the

char sustains.

But

what does hemp have to do with this? Hemp is one of the highest

yielding biomass crops on the planet, and it takes far less water and

fertiliser to grow than other high-yielding biomass plants. Seen as a

carbon sequester, hemp might give as much as 13 tonnes of charcoal

per hectare annually, which would outdo salix plantations (a popular

biomass crop) by about three times.

7)

We can stop using as much toxic herbicide and pesticide and restore

our soils

Hemp

has been on earth for a long, long time, and for millennia,

our ancestral

farmers grew it everywhere and

knew how to take full advantage of it. One of its main benefits was

in crop rotation. Until hemp became illegal to cultivate in the early

twentieth century, farmers regularly planted hemp as a part of their

crop rotation. Why? Because it naturally restored the fields for use

by other crops through numerous mechanisms:

Hemp

has been on earth for a long, long time, and for millennia,

our ancestral

farmers grew it everywhere and

knew how to take full advantage of it. One of its main benefits was

in crop rotation. Until hemp became illegal to cultivate in the early

twentieth century, farmers regularly planted hemp as a part of their

crop rotation. Why? Because it naturally restored the fields for use

by other crops through numerous mechanisms:

☮restores

vital nutrients into the soil.☮removes

chemicals from the soil (phyto-remediation)

☮naturally

killed off invasive plant species (weeds) without the use of chemical

herbicides.

☮relatively

pest-resistant, so entire hemp crops didn’t need to use pesticides,

allowing the field’s soil to be chemical free for the next crop’s

planting.

Hemp absorbs

CO2 and converts carbon dioxide into oxygen and improves the soil in

which it is grown. Sometimes used as a 'mop crop' and planted on some

farms to restore the soil’s nutrients during agricultural crop

rotation, hemp has the phyto-remediation potential to remove toxins

in the soil. Hemp offers real environmental advantages,

particularly with regard to the limited need for herbicides and

pesticides. Hemp is pre-adapted to organic agriculture and

accordingly, to the growing market for products associated with

environmentally-friendly sustainable production.

8)

We can reclaim land destroyed by pollution, radiation, and toxic

wastes

Hemp

is a member of an elite class of hearty plants that can naturally

extract and filter toxins and pollutants from some of the worst

disasters in the world, even radioactive soils. This is a process of

soil recovery known as phyto-remediation. Why use hemp as a

phyto-remediator?

☮high

biomass which is unaffected by pollutants

☮root can grow up to 2.5 metres (8 feet) below ground

☮low growing cost

☮quick growing season

☮full maturation in 180 days

☮good accumulator from air and soil

☮root can grow up to 2.5 metres (8 feet) below ground

☮low growing cost

☮quick growing season

☮full maturation in 180 days

☮good accumulator from air and soil

Contaminated

products can be used for industrial purposes: Bio-diesel fuels,

industrial lubricants and varnishes, insulation, construction

materials, paper, clothing, food and plasticised or composited

materials for a variety of uses.

A

number of studies have identified industrial hemp as a top candidate

in bio-remediation, especially phyto-extraction of heavy metals from

industrially contaminated soils. Hemp has been used to process

grey-water in Australia, extensively tested in Europe for the removal

of heavy metals from soil, including cadmium, lead, copper, zinc, and

nickel often associated with mining, used for the clean-up of

polycyclic aromatic hydrocarbons at a site in Hawaii and cultivated

on radionuclide-contaminated soils at the Chernobyl nuclear reactor

site.

9)

We can power coal-powered plants with much lower sulphur pollution

(or even none)

Coal.

A dirty word for many. A cheap source of electrical power for most.

And one of the most devastating sources of pollution in the modern

world. But we can cut emissions from coal plants by simply adding

hemp biomass to the coal being burned. By blending coal with

biomass materials such as hemp, sulphur emissions from power

generation can be reduced (by 40%) and less valuable coal that is

high in sulphur can remain competitive.

Even

more exciting is the prospect of bio-coal,

a complete alternative to replace traditional coal with almost no

sulphur emissions at all . Currently, most bio-coal is made from

wood, but as we know hemp has a higher cellulose content

(57-77%) than wood (38-49%) it stands to reason that as we begin

to grow hemp more efficiently and in more abundance, that we could

eventually derive more cost productive and efficient bio-coal from

hemp.

So,

all this information is great, but where are all these amazing hemp

products? Where’s the hemp?

Officially, hemp is still illegal to grow in many states across the US and in Australia the fledgling hemp industry has been trying to join the rest of the developed world and produce oil and food for human consumption. A prohibition on growing industrial hemp in Australia was lifted in the late 1990's, but Australian farmers are restricted to growing fibre and construction materials and politics has prevented them from

gaining access to booming hemp food markets (hemp isn't legal for human consumption in Australia and New Zealand).

Industrial hemp is grown by Australia's biggest producer on farms and facilities in New South Wales, Queensland and Tasmania, producing about 2,000 tonnes of raw material a year.

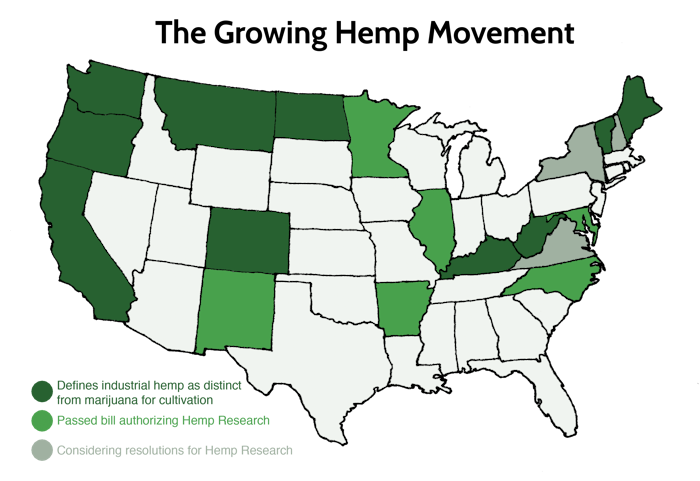

The US is finally getting 'turned on' by all the possibilities of hemp. With all that this amazing plant has to offer, and all the ways that it can change our world for the better, we need to support hemp growers, producers (and their products) and further research.

Adapted

from; 9

Ways Industrial Hemp Can Save The World

References;

Illegally green: Environmental Costs of Hemp ProhibitionStructural Benefits of Hempcrete Infill in Timber Stud Walls

No comments:

Post a Comment